Why is Calibration Important?

Calibration is essential in traffic simulation to ensure the model accurately reflects real-world conditions. It fine-tunes parameters like driver behavior, speed distributions, and capacity constraints to match observed data, making predictions more realistic and useful for decision-making. This process reduces uncertainty and enhances the model’s effectiveness in supporting transportation planning.

Calibrating a model is often a time-consuming process, based on a trial-and-error approach that adjusts input parameters until model outputs match real-world data. For the calibration of freeway models, Highway Capacity Software (HCS) provides a “Calibration Table” to help streamline the process.

Example – Calibrating Speeds

The example below shows a freeway facility with 11 segments that are being modeled in HCS. Detectors are available at each segment to provide field data:

Freeway facility sketch, with detectors for field data collection

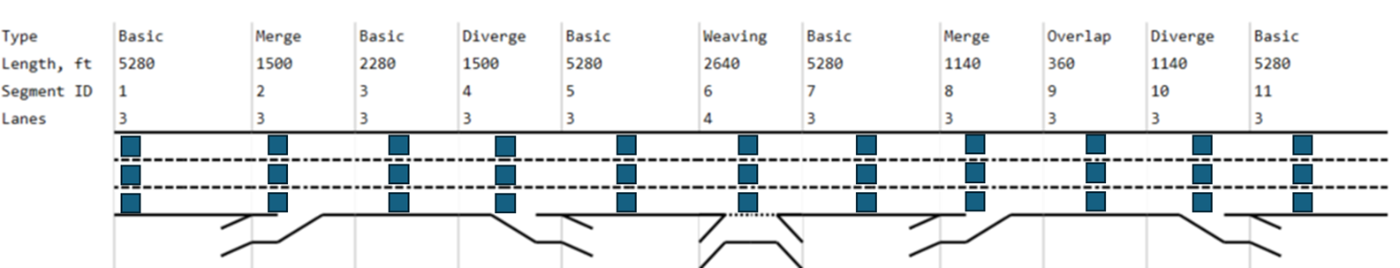

Next, a first HCS model is developed using all available inputs. Then, the average speeds computed in HCS are compared to field-measured speeds. As shown in the next figure, there are significant deviations between the results:

HCS speeds (uncalibrated model) vs. field-measured speeds

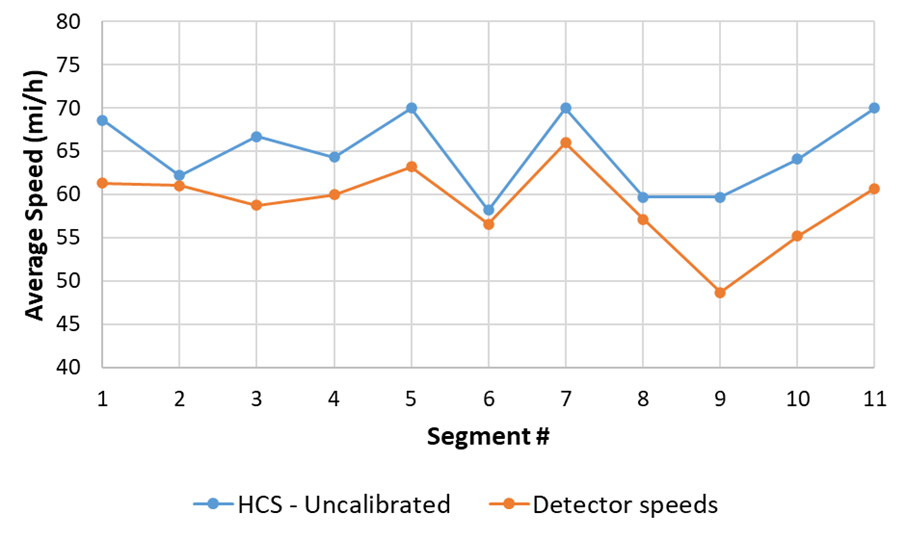

The Highway Capacity Manual (HCM) provides equations to estimate Free-Flow Speed, which is directly correlated to the computed speeds. However, the HCM models cannot always capture all elements that affect the actual speeds that vehicles will drive on the road, hence the need for further calibration. For this purpose, the “HCS Calibration Tool” (available in HCS top menu) allows the user to quickly apply Speed Adjustment Factors (SAFs) to adjust the Free-Flow Speed in the models. At the same time, the user can select one output parameter to be represented as the cell background colors, allowing quick visualization of the outputs as inputs are changed:

HCS calibration table before (a) and after (b) calibrating Speed Adjustment Factors

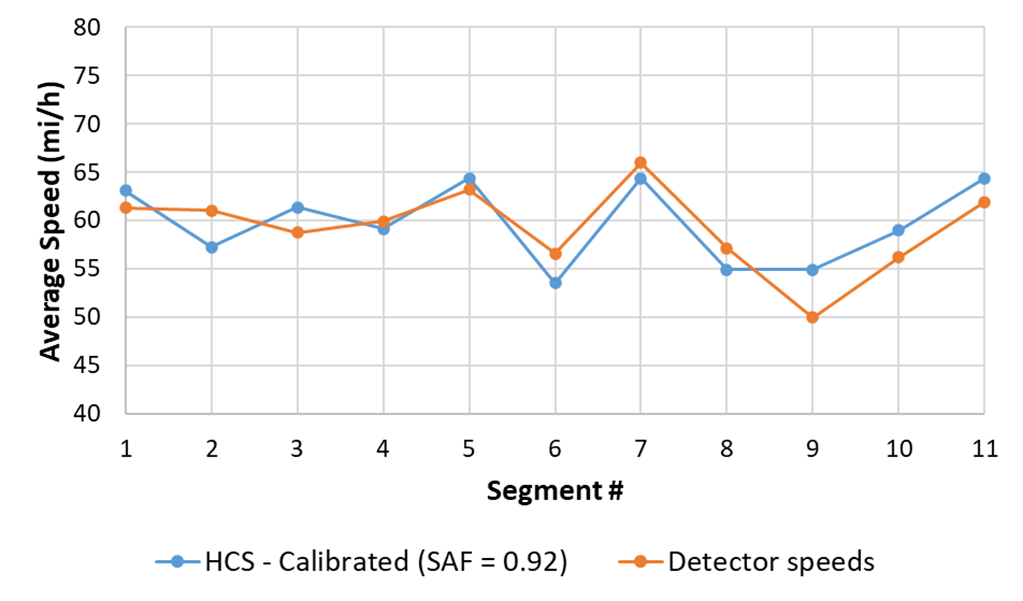

After a few different values for SAF were applied to this facility, it was found that a SAF = 0.92 yields the best results, with HCS speeds closely matching field estimates. The determination of the optimal solution can be done visually with a graph similar to the next figure, or quantitatively using statistical measures such as Mean Absolute Error and Mean Absolute Percentage Error.

HCS speeds (Calibrated model) vs. field-measured speeds

What Else Can be Done with the Calibration Tool?

The Calibration Tool can be applied to many different purposes, such as:

- Calibrating capacity at freeway bottlenecks, by applying different Capacity Adjustment Factors (CAFs) until the queue lengths computed in HCS closely match observed queues in the field.

- Evaluate work zone plans by applying CAFs and SAFs to simulate their impacts on freeway operations.

- Quickly adjust freeway volumes to simulate different design year scenarios.

- Adjust ramp volumes for further model calibration, for cases where detector data is unavailable for certain ramps.

For additional reference, the Highway Capacity Manual outlines a Freeway Calibration procedure in Chapter 25: Freeway Facilities Supplemental. This chapter is publicly available in the HCM Volume 4 website.