A freeway weaving segment is formed when merge segments are closely followed by diverge segments, with the on-ramp and off-ramp connected through an auxiliary lane. Weaving segments require intense lane-changing maneuvers because drivers must access lanes appropriate to their desired exit leg, and therefore, their performance is strongly influenced by geometric factors.

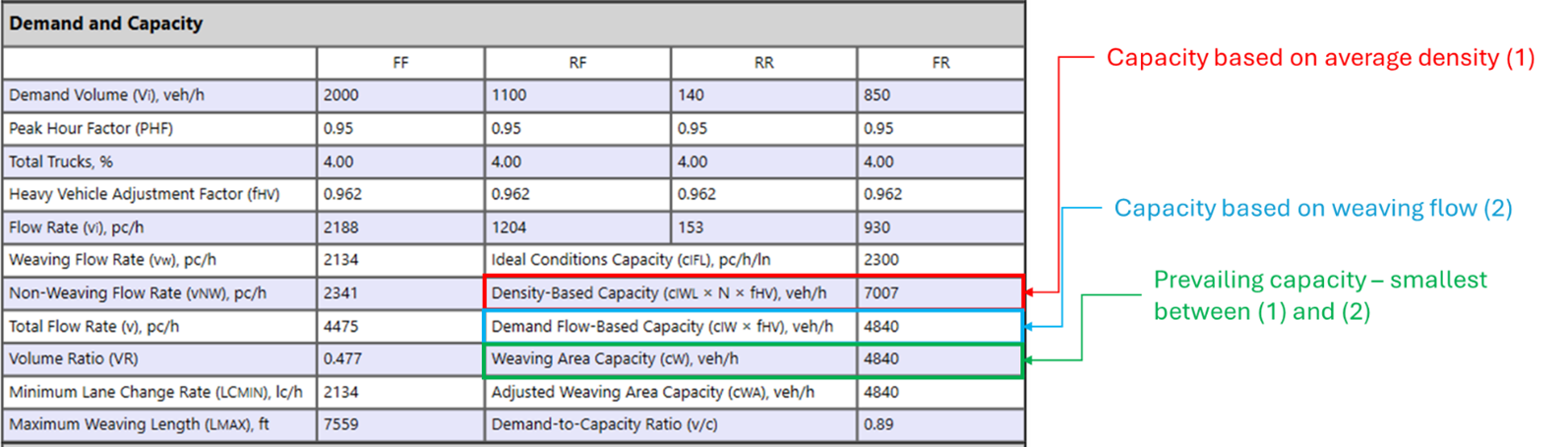

How is the weaving capacity determined?

Two factors can limit the capacity for a weaving segment:

- Average density across all lanes, limited to a maximum of 43 pc/mi/ln

- High proportion of weaving flows (represented by the parameter VR: volume ratio), causing the segment to fail due to turbulence and excessive lane changing

As shown in the figure below, the Highway Capacity Software (HCS) computes these two capacities, and takes the smallest between the two as the prevailing capacity:

The prevailing capacity is then compared to the demand. If the demand-to-capacity ratio (v/c) exceeds 1.0, oversaturated conditions will occur, yielding an automatic LOS F for the segment.

How can LOS for weaving be improved?

Different solutions can be adopted depending on which factor is causing the segment to fail.

If the weave is failing due to the average density across all lanes (1), the following treatments* can help improve LOS:

- Increasing the segment free-flow speed:

- Increased lane widths, wider right-side lateral clearance, and reduced number of adjacent ramps (3 miles upstream and downstream)

- Increase the weaving length (Ls): a longer weaving length allows vehicles to

- Increase the number of weaving lanes (NWL) from 2 to 3

However, if the weave fails due to the high proportion of weaving flows (2), the only parameter* that affects capacity is the number of weaving lanes NWL. In this case, increasing the number of weaving lanes (NWL) from 2 to 3 can significantly improve capacity and LOS.

What does it mean to increase the number of weaving lanes?

The Highway Capacity Manual defines “weaving lanes” as a lane “from which a weaving maneuver may be completed with one lane change or no lane changes”. The only feasible inputs for this parameter in the HCM methodology are 2 or 3.

Increasing the number of weaving lanes from 2 to 3 involves geometric changes in the lane alignment to provide drivers with higher flexibility in performing their weaving maneuvers, reducing turbulence.

A common approach to increase the number of weaving lanes is to add an Option Lane to the off-ramp, as illustrated in MUTCD, Figure 3B-11 (Sheet 5 of 6). In this configuration, the rightmost lane must exit, while the driver in the second-to-right lane may either take the exit or continue on the mainline.

*The capacity of a weaving segment is also affected by the Volume Ratio (VR) parameter, defined as the ratio of the weaving flow and the total flow in the segment. This article assumes the analyst does not have control over the demand volumes in the subject segment and does not consider this an alternative. However, some ATDM strategies to reduce the weaving volumes in the subject segment can also positively affect the weave LOS by reducing the computed value of VR.